It Pays to Know Syscom Tech

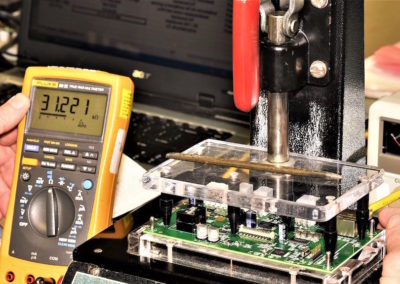

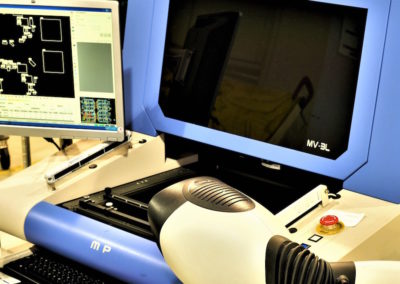

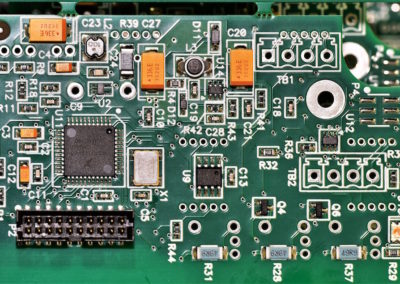

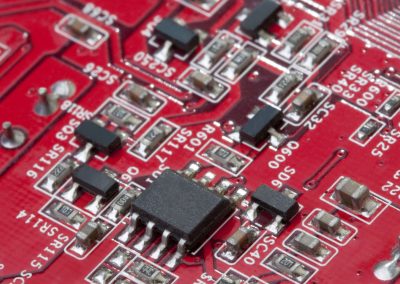

Quality Control Is Our Top Priority

With our Quality Control System, you can rest assured that our facility, capability and experience will meet your exact specifications and quality requirements. We code every component as it comes in the door for complete traceability. Every step of the manufacturing process is documented by signature with full line accountability and 100% testing.

We welcome you to tour our facility.

Proud U.S. Manufacturer

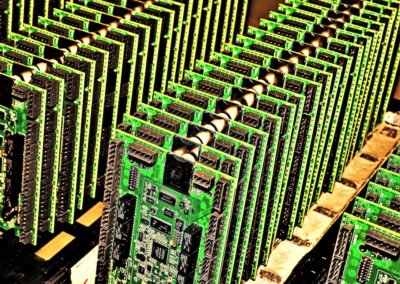

As one of America’s leading contract manufacturers, Syscom Tech provides full turn-key solutions as well as multiple stand alone value added services that transcend across all industries.

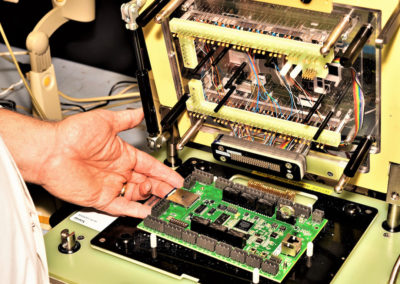

We have reinvested and upgraded our manufacturing platform with the newest technology—with the ability to manufacture and test for the smallest component size 01005 in the industry. Our labor costs are significantly lower than our competitors due to our fully automated distinct and independent assembly lines.

Optimize costs without threatening your

product quality or company reputation

Our People Are Our Greatest Asset

Together, our employees have hundreds of years of combined experience in the EMS industry. Our turnover ratio is well below the industry average, and our experience is second to none. Our Quality Control Program is supported by a fully documented quality system as well as employee quality training programs.

Functioning as long term partners, our dedicated support teams are responsive to changing supply chain requirements. With advanced knowledge, we provide valuable feedback on enhancing preproduction prototypes, transitioning from early-stage prototyping to mass production, and optimizing production schedules.

Clean Green Manufacturing

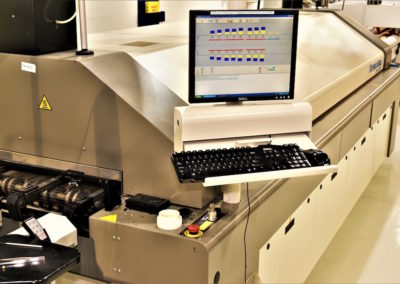

Syscom Tech is at the forefront of restructuring electronic manufacturing operations and processes to be more environmentally sustainable.

We are committed to helping the planet by minimizing our natural resource use and reducing emissions. By switching to solar energy, recycling and reusing formerly considered waste by-products, and reducing waste, we’ve been able to yield benefits to our triple bottom line

Recent Green Initatives

- In 2006, Syscom Tech secured the QC 080000 ROHS (Restriction of Hazardous Substances) Certification

- We use organic water soluble fluxes for our soldering process, and a lead-free solder

- Our water-based cleaning equipment recycles water for reuse

- In 2012, we installed a 156 Kw solar panel array onto the roof of our manufacturing facility